Custom Plastic Fabrication: Are you in need of high-quality plastic products tailored to your specific requirements? Look no further! Our custom plastic fabrication services offer a wide range of innovative solutions that will captivate your imagination. With years of experience in the industry, we pride ourselves on delivering exceptional results that exceed expectations. Our team of skilled professionals utilizes state-of-the-art technology and cutting-edge techniques to transform your ideas into reality. Whether you need prototypes for a new product, bespoke plastic components for a unique project, or customized plastic displays to showcase your brand, we’ve got you covered. Our commitment to precision and attention to detail ensure that every single piece we create is of the highest quality, meeting your specifications precisely. From concept design to final production, we work closely with you to understand your vision and bring it to life. With our custom plastic fabrication expertise, the possibilities are endless. Choose us for unrivaled craftsmanship, exceptional customer service, and prompt delivery. Experience the difference of custom plastic fabrication that exceeds your expectations. Contact us today to discuss your project and let us turn your plastic dreams into reality!

The Basics of Custom Plastic Fabrication

Custom plastic fabrication is a process that involves creating unique plastic products according to specific requirements and designs. This highly versatile manufacturing method allows for the production of a wide range of plastic items that are tailored to meet individual needs. From intricate prototypes to durable end-use products, custom plastic fabrication offers endless possibilities.

The Custom Plastic Fabrication Process

Custom plastic fabrication typically begins with the design stage, where engineers and designers collaborate to create a blueprint of the desired product. This blueprint serves as the foundation for the fabrication process. Next, the chosen plastic material is carefully selected based on its properties and suitability for the intended application.

Once the design and material selection are finalized, the fabrication process begins. It involves a series of steps, including cutting, shaping, and assembling the plastic components. Advanced techniques such as laser cutting, CNC machining, and thermoforming are often employed to achieve precise and intricate designs.

After the initial fabrication, additional processes such as polishing, painting, and coating may be performed to enhance the appearance and functionality of the product. The final step involves quality control checks to ensure that the custom plastic product meets the required specifications.

Applications of Custom Plastic Fabrication

Custom plastic fabrication finds application in numerous industries and sectors. Here are some common areas where custom plastic products are widely used:

1. Automotive Industry

The automotive industry relies heavily on custom plastic fabrication for various components. From interior trims and panels to engine parts and exterior accessories, customized plastic products play a crucial role in improving functionality, aesthetics, and overall performance.

2. Medical Field

In the medical field, custom plastic fabrication is instrumental in the production of medical devices and equipment. Custom-made plastic components are used in devices such as surgical instruments, implants, prosthetics, and diagnostic equipment. The ability to create tailored solutions ensures optimal performance and patient comfort.

3. Electronics and Technology

The electronics and technology industry extensively utilizes custom plastic fabrication for the production of casings, enclosures, and housings for various devices. These customized plastic components provide protection, durability, and aesthetic appeal to consumer electronics, industrial equipment, and electronic appliances.

4. Retail and Point of Sale Displays

Custom plastic fabrication is often employed to create eye-catching retail displays and point of sale (POS) displays. These displays can be customized to fit specific branding requirements and product dimensions. The versatility and cost-effectiveness of custom plastic fabrication make it an ideal choice for creating attractive retail displays that grab consumers’ attention.

5. Architectural and Interior Design

Architects and interior designers utilize custom plastic fabrication to bring their creative visions to life. From unique lighting fixtures and decorative panels to custom furniture elements, plastic fabrication allows for limitless design possibilities. The ability to create complex shapes and patterns makes it a valuable tool in architectural and interior design projects.

The Advantages of Custom Plastic Fabrication

Custom plastic fabrication offers several advantages over other manufacturing methods. Here are some key benefits:

1. Design Flexibility

Custom plastic fabrication allows for the creation of complex and intricate designs that may not be possible with other materials or manufacturing techniques. The versatility of plastics enables designers to turn their creative ideas into functional and aesthetically pleasing products.

2. Material Variety

With custom plastic fabrication, a wide range of plastic materials can be utilized, each with unique properties and characteristics. This allows for the selection of the most suitable material based on factors such as strength, flexibility, transparency, and chemical resistance.

3. Cost-Effectiveness

Custom plastic fabrication is often a cost-effective solution compared to other manufacturing methods, especially for small to medium-scale production. The ability to create custom designs and prototypes without expensive molds or tooling significantly reduces upfront costs.

4. Durability and Longevity

Plastic products created through custom fabrication can be engineered to be highly durable and long-lasting. The material’s resistance to corrosion, impact, and wear ensures that the final product can withstand harsh environments and heavy use.

5. Quick Turnaround Time

Custom plastic fabrication allows for rapid prototyping and production, reducing lead times significantly. This is particularly advantageous in industries where time-to-market is crucial, enabling manufacturers to quickly iterate and refine their designs.

In Conclusion

Custom plastic fabrication is a versatile and efficient manufacturing process that caters to a wide range of industries and applications. From automotive components to medical devices and retail displays, the possibilities of custom plastic fabrication are endless. With its design flexibility, material variety, and cost-effectiveness, it continues to be a preferred method for creating unique and tailored plastic products.

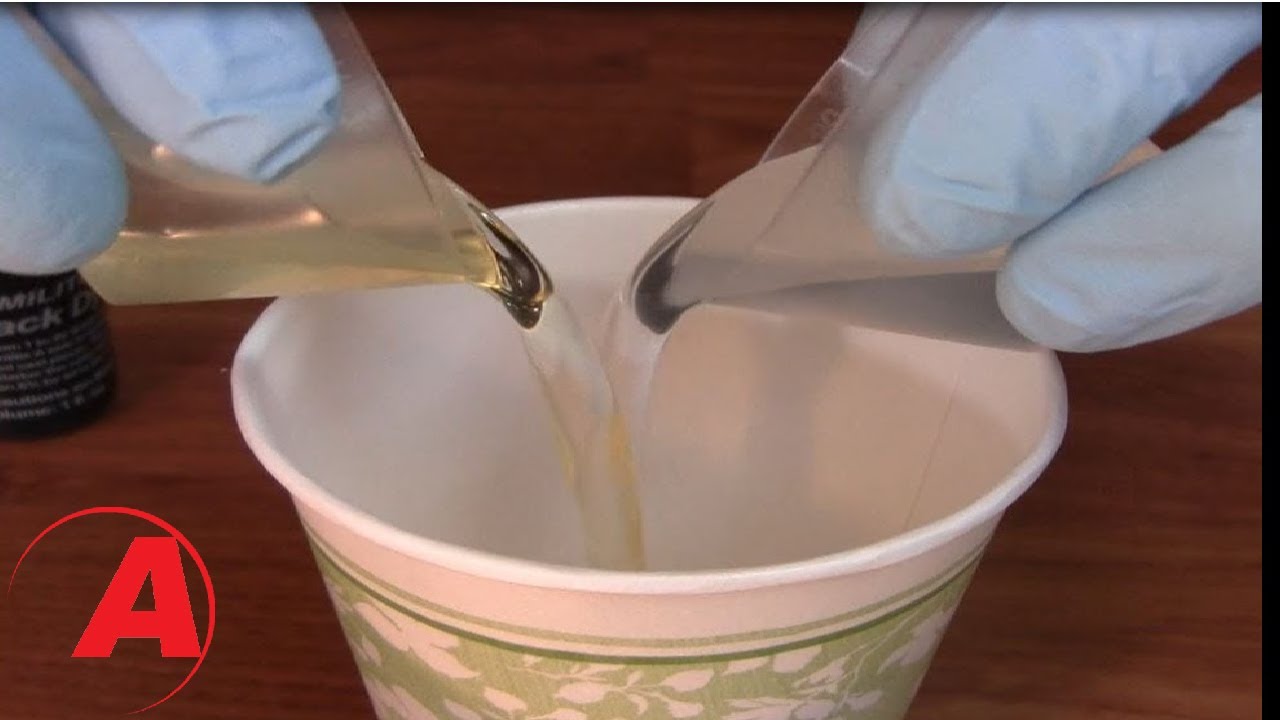

“Efficiently Craft Exceptional Plastic Parts: Unveiling the Alumilite Plastic Molding Tutorial”

Custom Plastic Fabrication

Custom Plastic Fabrication

| Material | Advantages | Applications |

|---|---|---|

| Acrylic | High clarity, UV resistant, Easily machinable | Display cases, Signage, Lighting fixtures |

| Polycarbonate | Impact resistant, Excellent transparency, Fire resistant | Safety shields, Machine guards, Automotive components |

| Polyethylene | Chemical resistant, Lightweight, Durable | Tanks, Containers, Cutting boards |

| Polypropylene | Heat resistant, Low moisture absorption, Good chemical resistance | Medical devices, Laboratory equipment, Packaging |

| Polyvinyl Chloride (PVC) | Low cost, Excellent electrical insulation, Flame retardant | Pipes, Fittings, Cable insulation |

Custom plastic fabrication involves the meticulous manufacturing of various plastic components tailored to specific requirements. This process requires expertise in selecting the right materials, understanding their unique advantages, and identifying suitable applications. The table above provides valuable insights into some commonly used plastic materials, their advantages, and the diverse applications they are well-suited for.

Acrylic, renowned for its high clarity and UV resistance, is a popular choice for manufacturing display cases, signage, and lighting fixtures. Its ease of machinability allows for intricate designs and customization.

Polycarbonate, prized for its exceptional impact resistance and transparency, finds extensive use in safety shields, machine guards, and automotive components. Its fire resistance further enhances its suitability for applications demanding high safety standards.

Polyethylene, known for its chemical resistance and durability, is commonly employed in the fabrication of tanks, containers, and cutting boards. Its lightweight nature makes it ideal for applications where weight is a critical factor.

Polypropylene, valued for its heat resistance, low moisture absorption, and chemical resistance, is often utilized in medical devices, laboratory equipment, and packaging solutions. Its versatility and reliability make it a top choice for demanding applications.

Polyvinyl Chloride (PVC), with its low cost, excellent electrical insulation, and flame-retardant properties, is extensively used in the manufacturing of pipes, fittings, and cable insulation. Its affordability and desirable characteristics contribute to its wide-ranging applications.

By leveraging the expertise in custom plastic fabrication, manufacturers can harness the advantages of these materials and deliver tailored solutions that meet the unique needs of their customers.